Product range:

The modern machinery park allows for rolling thick sheets up to 100 [mm] with a width of 4.5 [m]. These values may change depending on the sheet's bend radius.

Sheet metal rolling is performed with the use of sheets of the following types:

- Carbon steels such as S275, S355, P265GH

- Hardox plates

- Hardened and tempered steels

- Duplex and Superduplex 2205, S31803 steels

- High chrome steels

- Stainless steels such as 304L or 316L

- non-ferrous metals such as copper

- Special steels such as Hastelloy and Inconel

All our materials are supplied by approved suppliers and have metallurgical certificates. Our suppliers offer a range of material tests, including impact test, static tensile test as well as ultrasonic thickness measurement.

Sheet metal rolling is one of the services offered by IMPOSTAL.

Typical Applications:

• Energetics

• Construction

• The maritime industry

• Oil and gas industry

• Petrochemistry

INFORMATION ON SHEET ROLLING

PROCESSES

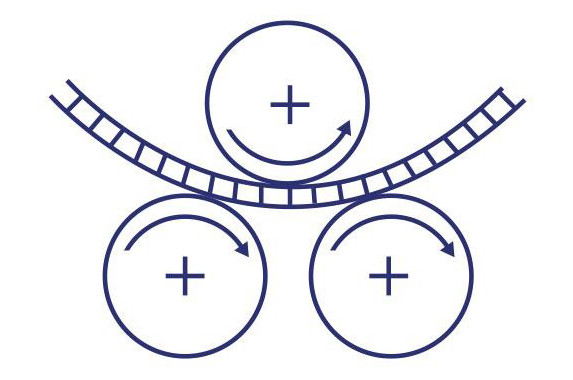

Coiling sheet metal in sheets by rolling sheets is a technique applicable to the entire spectrum of sizes and thickness and thickness of the material. In the coiling of metal sheets, three or four rolls are used to give the sheet the desired curvature. Through control

the distances and angles of the front arms can include the differentiation between variable shapes and radii after bending. Folding thick plates requires an additional pre-bending operation to prepare the end edges of the sheet for the actual bending. Movable side rollers ensure smooth control of bending curvature.

COILING OF THICK SHEETS

The range of acceptable ranges of sheets up to 4.5 [m] in length. Useful the latest edition of the most modern coilers in Europe, it is possible to cost-effectively coiling sheets up to 100 [mm] thick.

As a rolling process, it is flexible to meet customer's varying demands. We offer complete execution with material supply, as well as an outlet on entrusted materials.

The sheet coiling process has been audited by BSI in accordance with the ISO 9001-2008 standard. This ensures that the delivered product meets all the requirements.