Insulating 3LPE

ANTICOR B is a multi-layer coating. The letter B stands for the class of mechanical strength according to PN-EN 12068 and DIN 30672 (2004). The continuous working temperature of this coating should not exceed 30oC.

Coating marking according to PN-EN 12068: EN 12068 - B30 coating.

The basic structural layers are: primer, basic anti-corrosion protection tape and mechanical protection tape. In the single-belt system, the tape acts as both structural layers. By overlapping tapes with an overlap, sub-layers are produced in the structural layers.

The ANTICOR B system (class B-30) is mainly used for insulation of distribution pipelines (straight and curved sections of pipes, fittings, tanks, etc.).

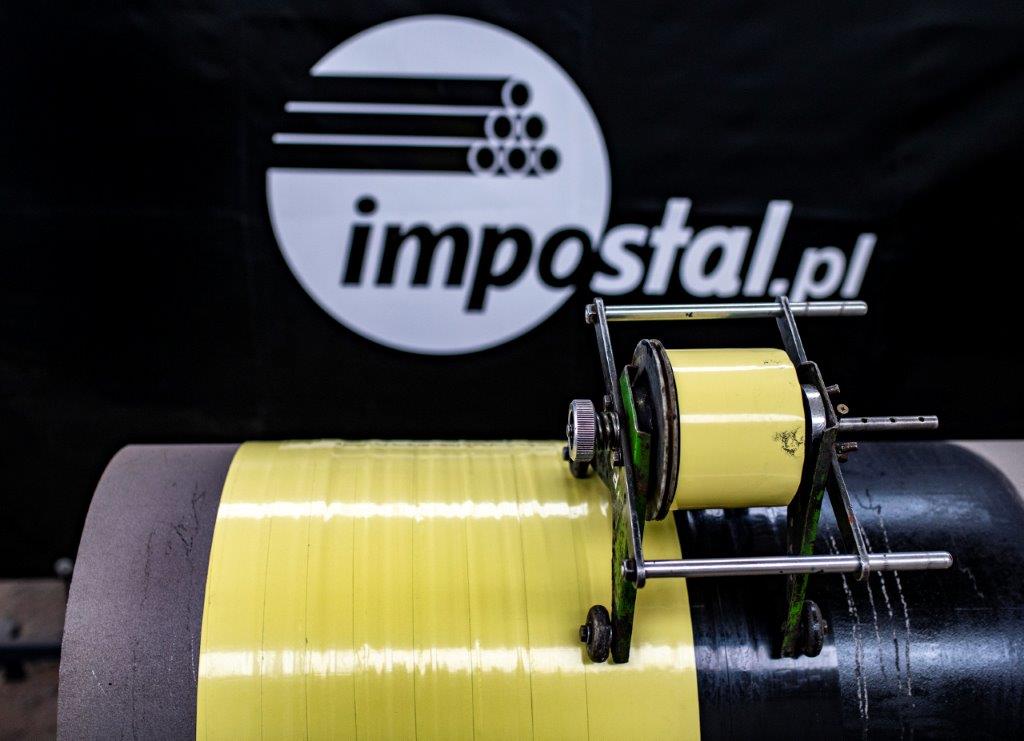

Tapes in individual layers should be wound spirally, manually or by machine (e.g. using the OWR-2 wrapping machine, supplied by ANTICOR), with pre-tension reducing the tape width by 1-2%. Apply the basic anti-corrosion protection tape (Polyken 989-20, 930-35) to the surface prepared to the degree of cleanliness according to table 2, dry and degreased, primed with POLYKEN 1027, after reaching the dust dry state. The temperature of the insulated surface should be at least 3 ° C above the dew point temperature. Primer must be thoroughly mixed before use. Please note that this is a flammable material! When applied in confined spaces, effective ventilation must be provided.

The temperature of the tapes during application should not be lower than + 4oC.

After application, the coating should be smooth, without wrinkles and air bubbles. The tabs should be equal. After about 1 hour from the moment of application of the coating, the adhesive layer (glue) should be visible from under the edges of the tape, due to the correct pretension of the tape.

The tightness of the coating should be checked with a spark flaw detector with a test voltage of 5 kV / mm of the coating thickness, but not more than 15 kV.

Additional information

Table 1 - Varieties of coatings

Table 2 - Basic parameters important for the selection of a coating

Table 3 - Material consumption and roll sizes